Exploring Smart Manufacturing and Technological Trends in Southern California's Engineering Ecosystem

- mehmet tezcan

- 22 hours ago

- 3 min read

At MATE Industry, we believe that understanding engineering and technology ecosystems requires more than just desk research. Our current fieldwork in Southern California involves direct engagement with production sites, technology-driven companies, and academic-industrial partnerships. This hands-on approach reveals how engineering choices, technology use, and regulations come together in real-world settings.

This blog post shares key trends we have observed across manufacturing, automation, and advanced engineering sectors in the region. These insights highlight how Southern California is shaping the future of smart manufacturing and engineering roles.

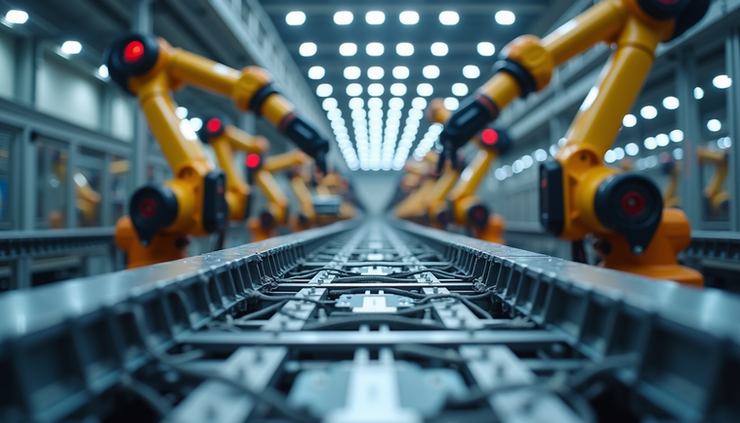

Automated assembly line with robotic arms in Southern California manufacturing plant

Smart Manufacturing Practices in Action

Smart manufacturing is no longer a concept but a daily reality in many Southern California facilities. Companies here use real-time data collection to monitor production processes closely. Sensors and connected devices feed information into integrated systems that help managers make quick, informed decisions.

One example is the use of digital twins—virtual models of physical assets or processes. These digital twins allow engineers to simulate changes and predict outcomes without disrupting actual production. This approach reduces downtime and improves product quality.

Beyond efficiency, smart manufacturing also focuses on traceability and long-term sustainability. For instance, some manufacturers track every component from raw material to finished product, ensuring quality control and compliance with environmental standards. This level of detail supports both customer trust and regulatory requirements.

Engineering Roles Are Becoming More Digitally Focused

Engineering jobs in Southern California are evolving. Traditional tasks like design and production are now combined with skills in data analysis, system thinking, and compliance management. Engineers are expected to understand how their work fits into larger systems and how to use data to guide decisions.

For example, an engineer working on a new product might analyze sensor data from previous models to identify potential failure points. They also document every step carefully to meet site-specific regulations and industry codes. This documentation helps during inspections and audits, making compliance a natural part of the workflow.

This shift means engineers must be comfortable with software tools, data visualization, and cross-disciplinary collaboration. Companies often provide ongoing training to keep their teams updated on the latest digital tools and regulatory changes.

Design Culture Driven by Inspection and Compliance

In Southern California, design processes start with compliance in mind. Instead of treating regulations as afterthoughts, engineers embed inspectability and code alignment into their initial plans. This proactive approach leads to designs that are easier to inspect, safer to operate, and more likely to pass regulatory reviews.

For example, a company designing a new automated system will consider how inspectors will access critical components. They might include features that simplify testing or monitoring without interrupting production. This foresight reduces costly redesigns and inspection delays.

By integrating compliance early, engineers create solutions that balance efficiency with safety and legal requirements. This culture also encourages innovation within clear boundaries, leading to practical and defensible engineering outcomes.

Final Thoughts on Southern California’s Engineering Landscape

Southern California’s engineering ecosystem shows how smart manufacturing and technology trends come together in practice. Real-time data, digital tools, and compliance-focused design are shaping how companies build and operate their systems.

For professionals and organizations looking to stay competitive, the key takeaway is clear: success depends on combining technical skills with a deep understanding of regulatory and operational realities. Direct exposure to production environments, like the fieldwork conducted by MATE Industry, offers valuable insights that desk research alone cannot provide.

As these trends continue, expect engineering roles to become even more integrated with digital and compliance functions. Companies that embrace this shift will improve quality, reduce risks, and build stronger connections between technology and real-world needs.

Comments